Preserving traditional craft

|

|

Than Van Thang (L) receives the collective mark protection certificate for Da Mai rice vermicelli. Photo: Ngoc Quyen. |

Thang is the sixth generation of his family preserving the vermicelli making craft. His base is capable of daily producing about 600 to 700 kilograms of rice vermicelli to sufficiently supply to 16 kindergartens, supermarkets, several restaurants as well as sell at Thuong market in the city.

Though he has recently inked a new deal with a canteen at Van Trung Industrial Park, Viet Yen district, Thang and other households have never provided their customers with unsold products in the previous day so as to protect their prestige. Without additives and chemicals, the vermicelli strips are naturally soft and tough with special taste. Da Mai rice vermicelli is distinguishing from the same product using additives and chemicals by its darker color instead of the shining appearance. Thang’s production base has to use about fifty 120- liter barrels to soak rice and powder to make different batches of vermicelli for

Currently, vermicelli making steps of rice washing, grinding, crushing and are facilitated by machine, helping to ease the craftsmen at work. The rice for making vermicelli is a popular type. It is washed by the machine, soaked in clean water for 12 hours until it gets soft, then it is ground into powder. The powder will be soaked in clean water in the specialized barrels. It takes 8 to 10 days in winter and only 2 to 3 days in summer to soak the powder for fermentation so as to make good vermicelli with proper softness and natural tastes. If the powder-soaking time is not ensured, vermicelli making will be failed.

According to Thang and other local craftsmen, rice and powder soaking time can be reduced by the chemicals and additives which can save the costs, increase the productivity, create eye-catching white vermicelli strips with longer preservation period. However, they are determined to conserve the “good fame” of Da Mai vermicelli-making village, refuse the temporary benefits to ensure the food hygiene standards.

|

|

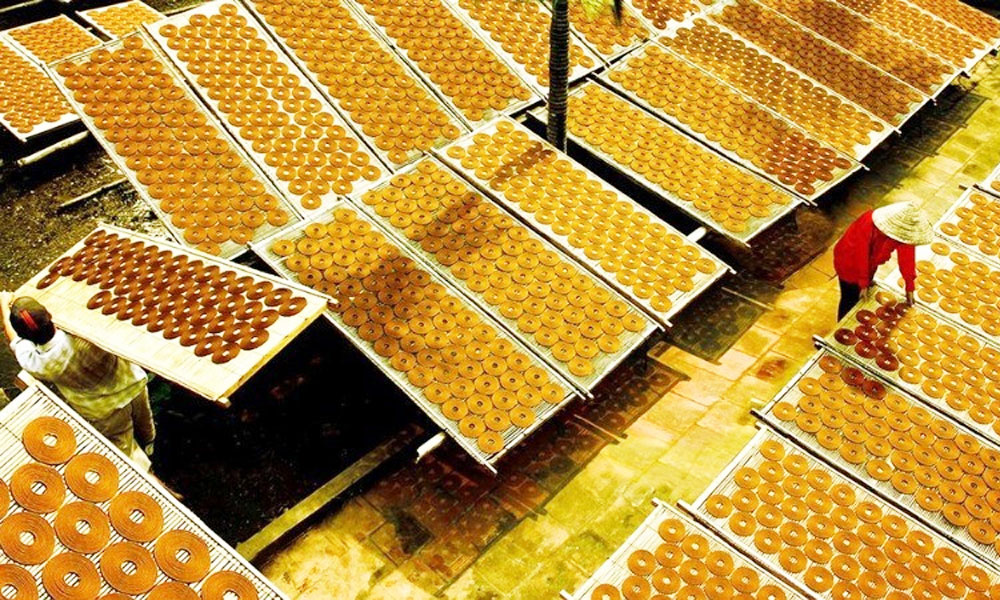

The production base of Than Van Thang. Photo: Do Quyen. |

The powder is soaked for a proper time, pressed sour water out, stirred and put in the integrated machine to be whisked in clean water. The following steps include pressing the finished powder by a strip

Thanks to the determination to preserve good fame of the craft village, Da Mai vermicelli was granted the collective mark protection certificate in 2017 by the Vietnam National Office of Intellectual Property (Ministry of Science and Technology).

On March 2018, under the guideline of Da Mai ward, Thang established and managed Thang Thuy Da Mai clean vermicelli- making cooperative with 13 members. Additionally, he continues investing to upgrade a bigger scale production line with higher productivity. Besides, the cooperative has proposed the Bac Giang municipal Division of Economic Affairs to support them in dealing with procedures for traceability stamp so as to affirm their prestige to the consumers.

My Binh

Bắc Ninh

Bắc Ninh

Reader's comments (0)